![[Bitte in "English" uebersetzen:]](/fileadmin/_processed_/0/c/csm_Header_Produkte_Ingersoll_Werkzeuge_GmbH_4c72f5296e.jpg)

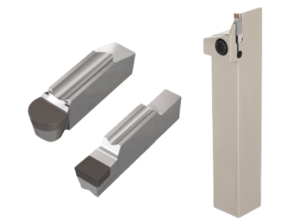

New Anti-vibration shanks

- Higher process reliability under unstable conditions

- Up to 10xD overhang without loss of performance

- Excellent surface quality due to reduced vibrations

- Extended tool life due to the carbide body with high wear resistance

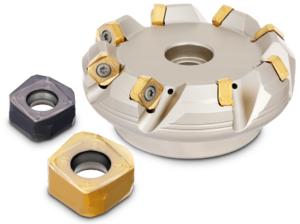

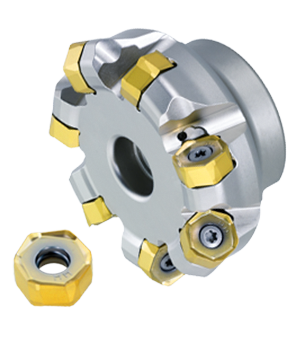

Finish mill 6F6S

- 4-edged tangential indexable insert

- Shortened wiper edge

- Maximum feed rates

- Easy handling

- Top-quality surfaces without wiper adjustment

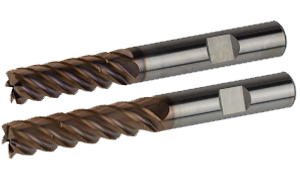

High-Performance Trochoidal End Mill for Roughing

- For efficient roughing

- Stainless steels and titanium

- High metal removal rate

High-Performance End Mill for Roughing amd Finishing

- Versatile in use

- For difficult-to-machine stainless steels

- High metal removal rate

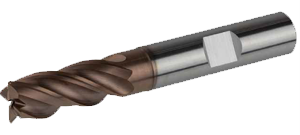

High-Performance Aluminium End Mill for Roughing amd Finishing

- Precise and efficient machining

- Vibration-free machining

- Heel-free machining

- High tolerance accuracy

Indexable Thread mills MTET (ISO / 60°)

Indexable thread mills MTET (ISO / 60°)

- Flexible

- Economic

- Process security

- For internal and external threads

Thread mill MTECBF

Thread mill MTECBF for:

ISO-Thread (Internal)

UN-Thread (Internal)

BSF/BSP-Thread (Internal / External)

- Max. no. of effective teeth

- Improved stability

- High feedrates

- Short machining times

- Excellent surfaces

- With internal coolant

Solid carbide thread mill

SOLID CARBIDE THREAD MILL MTECM-MTECK (60°)

- Reduced cutting forces

- Shortened machining time

- Minimized radial deflection

- Superb chip evacuation

- For internal threads

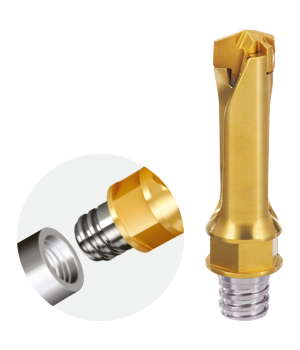

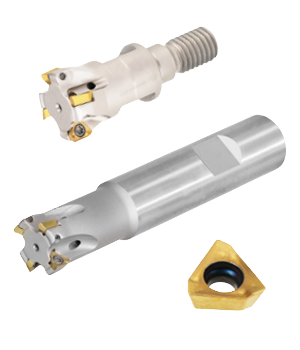

Quick change solid carbide head

Quick change solid carbide head for multiple machining

- More cutting edges for maximized productivity

- Simple and robust precision mounting system

- Highly efficient face & shoulder mill 90°

- Thread milling 55°/60°

- Slot milling

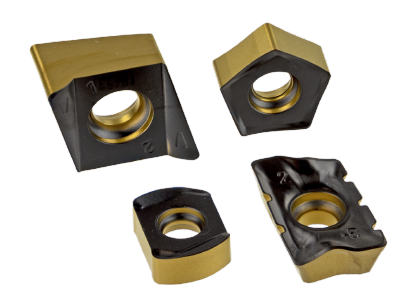

DNGX-ST insert

DNGX-ST insert for deep depth of cut machining

- 4-corner double-sided insert

- 5.0 mm maximum depth of cut

- Continuous chip ensures low cutting force and precise machining dimensions

- Recommended for use with the servo oscillation function in Swiss type machines

- Higher rake angle design for low cutting force

- Compatible with RhinoTurn holders

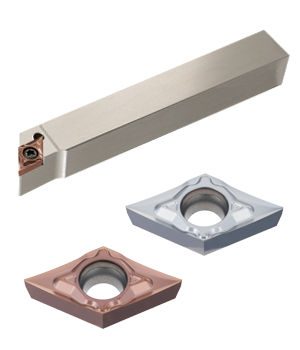

TTurn DCGT-ST insert

DCGT-ST insert for deep depth of cut machining

- 2-corner positive insert for small part machining

- 5.0 mm maximum depth of cut

- Higher rake angle design for low cutting force

- Compatible with ISO turning holders

New TTurn PCD CF chipbreaker for super finishing in nonferrous machining

PCD CF super finishing chipbreaker

- For super finishing in nonferrous machining

- Capable of fine chip segmenting even in low depth of cut machining

- Segmenting reduces machine downtime

- Increased productivity

New ML chipformer for a variety of machining materials

New ML chipformer for SQGU11/SQGU14 inserts

- A new holder with a protruding head capable of deep depth of cut operations in shoulder machining

- Sharp cutting edge

- Suitable for long chip applications or tough ISO M material machining

- Better performance due to its smoother cutting

- Higher productivity

Head offset type holders launched

Head offset type holders launched for turning and grooving applications

- A new holder with a protruding head capable of deep depth of cut operations in shoulder machining

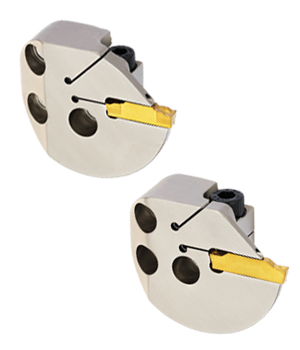

Expansion of triangular blades and blocks

New triangular blades and blocks for parting and deep grooving with internal high-pressure coolant

- Switching hand types minus turret change

- Rigid clamping for excellent durability and repeatability

- User-friendly and rigid insert clamping system

- Improved chip evacuation

- With CoolBurst high pressure coolant system •

Grooving and profiling CBN inserts for hard material machining

Grooving and profiling CBN inserts for hard material machining

- Compatible with TClampUltra+ holders for a diverse range of applications

- Excellent surface finish

- TB2015 grade

- High wear resistance and optimal toughness

High speed machining spindle

Small high-speed jet spindle for coolant to the tools

- Powerful, accurate milling & drilling in difficult-to-reach spaces

- Pinpointed coolant to the cutting edge

- Simple tool change with no setup time

- Improved dynamic balancing due to nutless collet

- Low runout

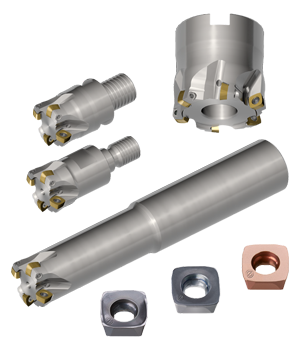

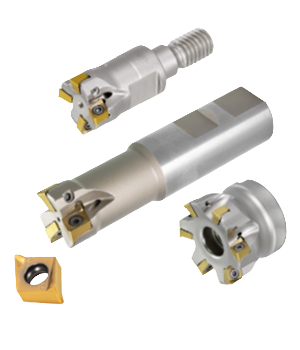

High feed mills 15G1D_/5G1D

High feed mills 15G1D_/5G1D with insert SDXS06

- Very smooth cutting geometry

- 4-edged inserts

- 3 different insert geometries in 3 different carbide grades each

- Shell-type and screw-in type cutters with TopOn and TS-adaption

- Cylindrical end mill

- Diameter range of cutters: Ø16 - 50 mm

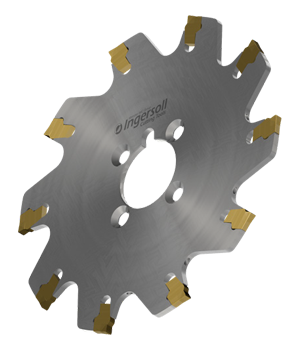

Slotting cutters SSC

New WinCut slotting cutters in modular design

- Standard tools in diameters Ø80, Ø100, Ø125 and Ø160 mm

- Cutting widths 2 mm and 3 mm

- Strong cutting edges for maximum productivity

- Precisely directed internal coolant supply

- Designed with flat front and free of interfering contours

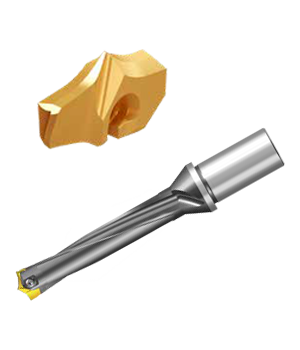

Head changeable modular drills with ChipSurfer connection

Head changeable modular drills with ChipSurfer connection

- Simplified clamping system due to ChipSurfer connection

- Modular design with interchangeable heads

- Reduced tool change and set-up time

- Easy use on Multi-spindle and Swiss type machines

- Available in internal coolant type

Double-sided 4 corners negative insert and holders

4 cutting edge inserts and holders for all-directional turning including high feed backward turning

- Excellent chip control

- Higher productivity

- Strong insert clamping force

- High-pressure coolant supplying

- Improved machining performance

New grade IN3305 with TA-C-coating

Solid carbide cutters for aluminium machining

- High hardness of over 5000 HV

- Thin coating for sharp cutting edges < 1 μm

- Low coefficient of friction

- High oxidation resistance at high temperatures

Precision round type single-ended insert TST

TST Precision round type insert

- For external and internal profiling, turning and grooving applications

- Precision machining and excellent repeatability

- Low cutting force and good surface finish due to the insert’s sharp cutting edge

- Good chip control over a wide medium-to-finishing machining range

- TT3010 grade provides excellent tool life in super alloy machining •

New Cartridges and Holders for External Turning and Grooving

New Cartridges and Holders for External Turning and Grooving

- Cartridges of different sizes fit in the same holders

- Unique clamping mechanism

- Stable cutting performance with excellent rigidity and precision

- Shorter set-up time, increased productivity and simplified inventory

New grooving heads for TClampUltra+ inserts

New TModular heads for improved internal grooving of deep holes

- Internal grooving heads range: 2-6 mm

- Fitting to TAbsorber shanks and head changeable CAdapters

- Pinpointed coolant supply to the insert's cutting edge

- Improved tool life and chip removal

- Good surface roughness

Modular threading heads

New heads for deep internal threading

- Modular threading heads for 16 & 22 IR/L inserts

- Fitting to TAbsorber shanks and head changeable CAdapters

- Pinpointed coolant supply to the insert's cutting edge

- Improved tool life and chip removal

Slotting Cutters with new TriLink Connection

- Ø40, Ø50 and Ø63 are now standard

- Precisely directed internal coolant supply

- Designed with flat front and free of interfering contours

- Modular system

Cutters and inserts of FNKT05 line for miniature machining

- Minimum tool diameter: Ø6 mm

- Strong insert clamping

- Increased productivity

- Excellent chip evacuation

- Improved tool live

- Wide range of applications

Self-centering drill heads LPC

- Excellent hole accuracy and premium surface finish

- Improved cylindricity and straightness

- Rigid clamping for reliable performance and long tool life

- reduced cycle and tool change time

- Head dia. range: Ø20-34.5 mm (0.5 mm increments)

- Optimally for steel and cast iron

7XD Holder for deep hole drilling

- One drilling head covers various drilling depths: 3xD, 5xD, 7xD

- 7xD drill diameter range: 26-41 mm

- Through-coolant hole system

- Improved machining stability

- Increased tool life

3-flute flat head type FPF_

- Excellent hole accuracy and surface finish

- Improved productivity and cost reduction

- Compatible with the current TwistSFeed holders

- Head diameter range: Ø12.0-25.5 mm (0.5 mm increm.)

- Centering point geometry for high tolerance hole precision

- IN2205 grade provides high resistance of wear and chipping

- Prolonged tool life

8XD Holder and heads for deep hole drilling

- Wider drill head diameter range: Ø12.0-25.5 mm

- 3-flute geometry for improved productivity

- Self-centering geometry for high tolerance hole precision

- Head exchangeable drills reduce tooling downtime

Double sided 8-edged insert SQGU10

- Economical, double-sided 8-corner insert

- Precision 90-degree machining

- Insert's wiping flat improves surface finish

- Reinforced cutting edge enhances machining stability

8-edged inserts SQGU11/14 and cutters

- Two different lead angles cutters for roughing and high feed machining

- Wiper edge for excellent surface roughness

- Reinforced edge optimized for high feed machining

- Excellent chip evacuation due to reduced chip volume

- Enhanced body rigidity for excellent machining performance

- Fine pitch cutter maximizes productivity

Lens and champfer barrel inserts

- Improved productivity and surface roughness compared to ball type inserts

- Larger radius cutting edges

- Compatible with the existing FineMold+ holders

- Stable clamping system

- Excellent runout and repeatability

- Internal cooling directly on the cutting edge

8XD Drilling depth and new flat bottom geometry

- Drill range: Ø4.0-12.0 mm (0.5 mm increments)

- 3-flute design improves productivity

- Stable drilling under high cutting conditions

- Polished, optimal geometry flutes enable smooth chip evacuation

- Internal coolant through-type solid carbide drills

- Two machining steps reduced to one

UNLV insert with V-shaped contact face

- 4-edged insert

- Stronger clamping due to insert's V-shaped design

- Improved tool life

- Excellent machining performance

- Various application range

- Good ramping ability

Head changeable modular drills with 12 mm srew-in connection

- Wide range of applications

- Modular design with interchangeable heads

- Reduced tool change and set-up time

- Easy use on Multi-spindle and Swiss type machines

- Available in internal coolant type

- Boring depth: 3xD

- Diameter range Ø6 - 20,9 mm

Ultra small CGM101/CGX101 inserts and end mills

- Strong tangential type 4-corner insert

- Exact 90 degree shouldering

- Optimized geometry for smooth machining and improved stability

- Capable of straight and helical ramping machining

- Enhanced cutting stability

Ø8-12 mm Reamer heads 3XD and 5XD holders

- User-friendly, ingenious clamping system

- No set-up time and minimum machine downtime

- Higher productivity compared to solid reamers

- Excellent hole accuracy and premium surface roughness

- Straight type and helix type heads

- Direct coolant supply to each cutting edge

Extension with Ø4,0 - Ø5,9 mm in 3XD and 5XD

- Diameter range from Ø4.0 mm to Ø5.9 mm in 0.1 mm increments

- Eliminates the need for extra set-up time

- Excellent machining performance

- Available in two holder depths: 3xD and 5xD

- Twisted coolant supply

Copy end mill for finishing 12L8/M8/N8

- Double-sided, four-corner barrel insert

- 2 radius sizes R20/R30

- Great roughness

- Large path distance = short machining times

Single-ended rigid inserts and holders SFER/L & SFGB

- Rigid clamping for excellent durability and repeatability

- User-friendly and rigid insert clamping system

- Improved chip evacuation

- With CoolBurst high pressure coolant system

Modular changeable head system

- Easy replacement of modular heads and inserts

- Improved productivity owing to reduced set-up time

- Rigid clamping between shanks and heads, and good repeatability

- Reduced inventory due to the ability to mount multiple heads on one shank

TNMV Inserts & TTQNL holder

- Excellent chip control

- Higher productivity

- Strong insert clamping force

- High-pressure coolant supplying

- Improved machining performance

VBMX Insert & holder

- Powerful clamping minimizes insert rotation

- Excellent surface finish

- Precise machining dimensions

- Stable tool life and excellent machining performance

- Suitable for finishing

Multipurpose TDXC insert

- Reinforced edge for high feed grooving and parting applications

- Stable machining performance

- Optimized turning chip breaker according to depth of cut

- Width sizes 2, 3, 4, 5 and 6 mm

- Compatible with existing standard holders

Multifunktional V-Type insert TDMV

- Versatile chip breaker and superior chip control

- For a variety of tasks in tight spaces

- Roughing and finishing capable

- 4 insert types: R/L-handed, corner R0.2, R0.4

- Reduced tool cost and equipment downtime

- Compatible with standard holders

Insert line expanded to 2 mm width

- Expanded to 2-4 mm width inserts

- Robust insert and screw clamping design

- Thicker insert design for higher stiffness

- Wide variety of applications

- Good chip evacuation and stable tool life

Ø80 MM Anti-vibration boring bars

- Good surface roughness and improved tool life

- Shank diameter: Ø80, length: 7xD, 10xD

- Available in various dedicated head types

- Dedicated adapter use a 20x20 standard square holder

- Internal coolant type

Extra wide grooving inserts and holders

- Economical 4-wide cutting edges insert blank

- Insert blanks in 3 different widths: 10, 15 and 20 mm

- Smart clamping holder design

- Stable and robust insert mounting

- CoolBurst high-pressure coolant

Small hole internal grooving insert & holders

- Improved economy compared to solid carbide tools

- Unique inclined clamping system

- Small bore internal grooving and internal bottom grooving

- Excellent machining performance

- Smooth chip evacuation

- Increased tool life

Exchangeable head system

- Excellent machining stability

- Very strong increase in productivity

- Compatible with T·ABSORBER heads

- Excellent chip evacuation

- Y-axis turning heads

I•Absorber prolongation vibration damped

Our proven InnoFit modular adaption system is expanded by a I·Absorber vibration damped prolongation for shell type milling cutter in the length of 200 mm. This new I·Absorber prolongation can be combined with all standardized spindle adaptors and solid prolongations.

The vibration damped prolongations are available for centering-Ø27, -Ø32 und -Ø40 mm at first in the modular Z5-size, i.e. outer Ø of 78mm, the smaller Z4-size with outer Ø of 61mm will follow soon in centering-Ø22 and Ø27.

Chip•Surfer Thread Mill 17Y_/18Y_ 55°/60°

The new screw-in type thread milling cutters are an addition to the existing ChipSurfer series 17Y_/18Y_ in partial profil range 55°/60°.

This cutter series has ChipSurfer connections in maximum diameter range for reliable and highly effective machining, even in deep threads.

Premium ball nose mill

The special Ingersoll HPC geometry offers multifunctional applicability of the ball end mills and meets the requirements for machining common material groups. The excellent roughing-finishing geometry can easily be used in different machining strategies.

The cutting edge geometry together with the coating technology ensure multifunctionality in all common material groups.

TDT...-RS Precision roundtype insert

The TDT… -RS precision round type insert provides excellent surface fi nish for external and internal profi ling, turning and grooving applications.

A sharp cutting edge due to the ground fl ank face and high rake angle reduces cutting force, therefore provides good surface fi nish and longer tool life.

New TDXY Insert

New TDXY Insert for Multi-Purpose Grooving and Turning Applications

The TDXY insert is designed for various applications: external, internal and face grooving as well as turning applications. High feed capability due to the reinforced edge strength and optimal chip breaker result in improved productivity. The insert line enables good performance even in both continuous and interrupted cutting conditions; the straight front cut-ting edge shape not only enables a flat bottom surface when grooving but also improves tool life by minimizing chipping and notch wear.

70 Degree Corner Angle XNMV1105 Insert

Ingersoll has expanded the RhinoTurnX line by adding the 70-degree corner angle XNMV1105 insert for multidirec-tional and high feed turning applications. The RhinoTurnX line dramatically improves productivity due to its all-directional and high feed turning capabilities.

High feed mills and inserts UNLU_

High feed mills and inserts UNLU04/-06/09/-11

- Insert with 4 cutting edges

- Improved productivity

- Smooth cutting and excellent insert rigidity

- Applies to a variety of applications

- 4 insert sizes with 2 resp. 3 geometrys each and 4 different grades

High feed mill 15G1B

- Very smooth cutting geometry

- 4-edged insert

- 2 different insert geometries with 3 different carbide grades each

- Screw-in type milling cutter with TopOn and TS-adaption

- End mill cylindrical

- Tool diameter range: Ø10/12/16/20/25 mm

90° End Mills with small 4 mm inserts

for THLS04

- True 90° milling solution

- Small 4 mm inserts

- High positive geometry for low cutting force

- Maximized productivity

90° Shoulder mills with 4-edged inserts

MNHU04 /_09/_11/_14

- True 90° shoulder milling capability

- High positive geometry

- High ramp down angle

- High productivity due to fine pitch cutters

45° Face mills

DN_H/G with 12-edges inserts

- High productivity and reliability when machining at aggressive feeds

- Maximized cutter body stiffness and enhanced cutting edge

- Smooth machining and excellent chip evacuation

- Minimized vibrations

Grade IN6537

New optimized Grade for General Purpose, High-Speed and High-Feed Machining of Steel

- Optimized for high-speed and high feed machining of steel

- Stable tool life

- Wide application range

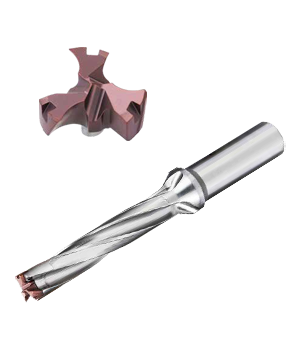

Deep hole drilling TD

Modular drill bodies for deep hole drilling with GoldTwist drilling heads

As part of the new innovative SFeed products, Ingersoll is introducing the modular DeepTwist tool for deep hole drilling operations. The modular DeepTwist "TD" part-hole drills in a stable design offer optimum performance, even with workpiece materials with a tensile strength over 1000 N/mm². The solid material design makes it possible to transmit high torsional forces.