The Printed Future!

Additive Manufacturing of Cutting Tools

Start into a new dimension of machining with Ingersoll CUBE 3D. With creative Ingersoll engineering and additive manufacturing, we optimize your machining process and make amazing things possible.

Ask your Ingersoll Partner about CUBE 3D

Our Offering

Dimensions, Lot Sizes and Delivery Times

Maximum Dimensions

We can offer you additive tools up to a diameter of 325 mm and a length of up to 335 mm.

Minimum Quantity: 1 piece!

We would like to convince you of the performance of Ingersoll CUBE 3D. Therefore we gladly offer you order quantities of just a single additive tool.

Delivery Time

If it needs to be quick, we can also offer the lead times you know from Ingersoll Extreme.*

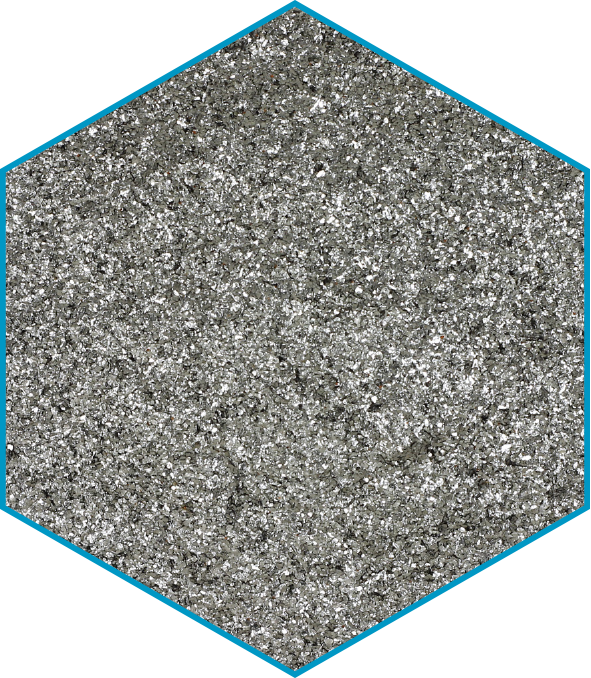

The Powder

Ingersoll exclusively uses premium tool steel powder for additive manufacturing.

The Process

Precisely controlled lasers melt the powder. The material produced complies to the Ingersoll standard in terms of density, strength and composition.

The Additive Tool

The additive manufacturing process opens up completely new possibilities for optimizing the function and economy of cutting tools.

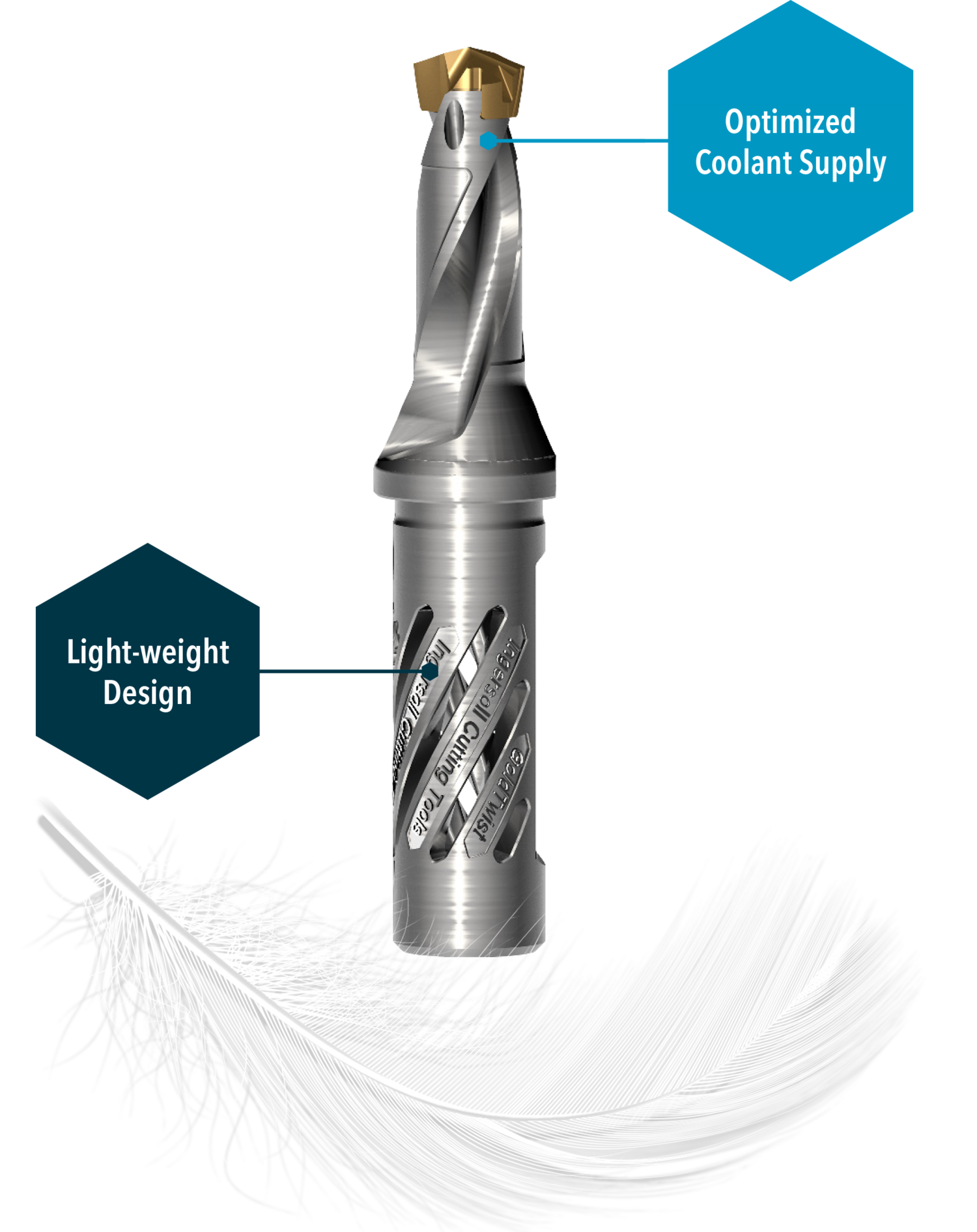

Drills

Optimized cross-sections and chip gullets can be achieved through a customizable coolant channel design - while gaining more rigid tool bodies along the way!

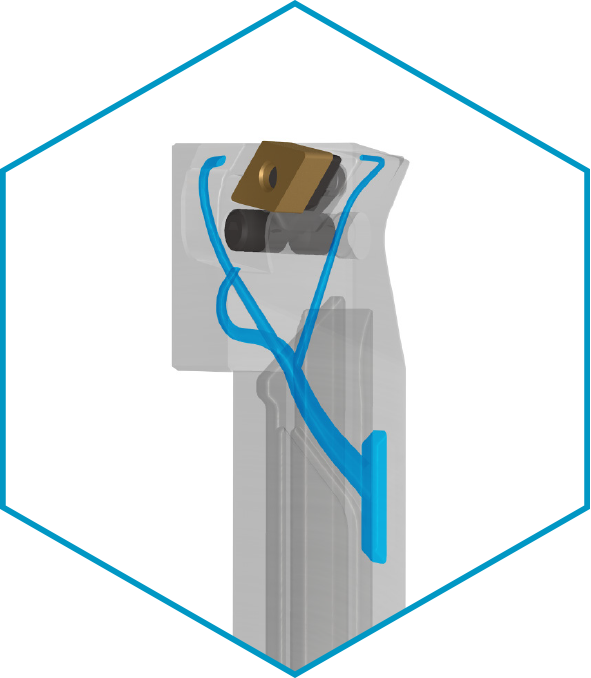

Turning Tools

CUBE 3D is ideal for sophisticated special turning tools with high-pressure cooling.

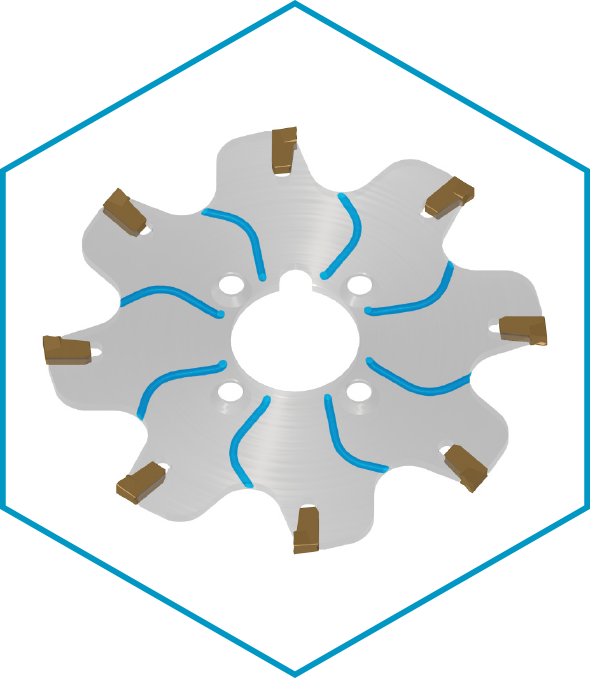

Slitting Tools

Applications such as slot milling, cut-off or groove turning that require cutting tools to be narrow or thin are excellent opportunities for Ingersoll`s additive capabilities CUBE 3D.

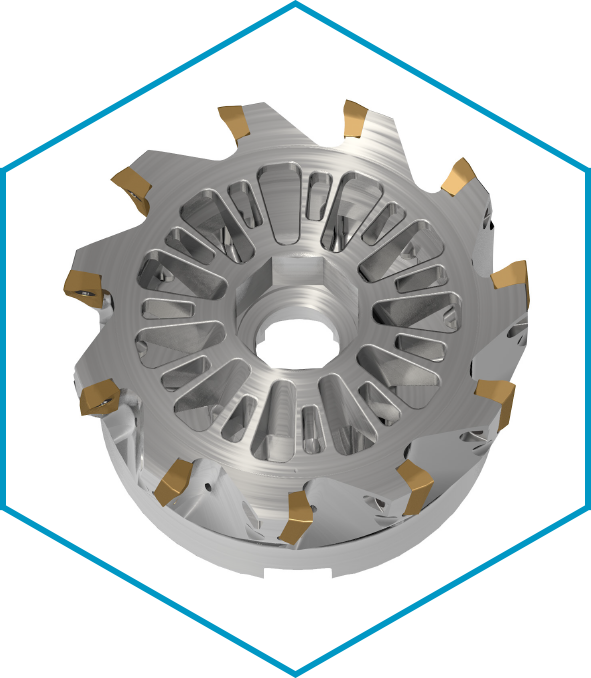

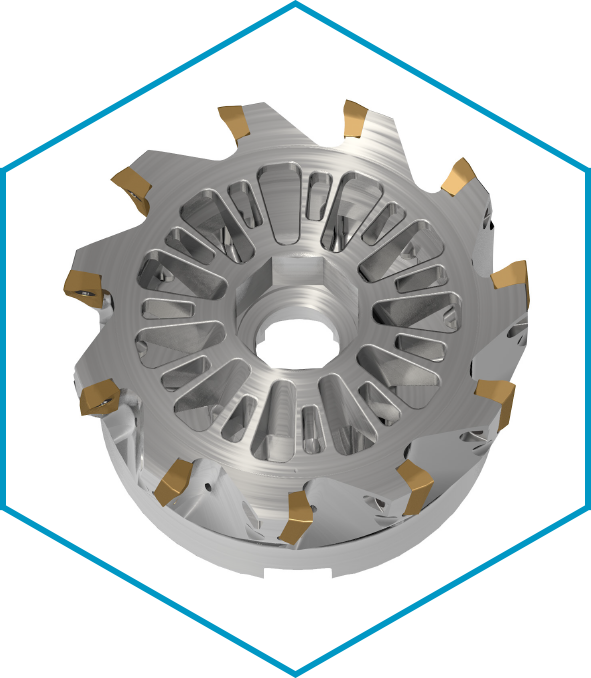

Milling Tools

Light-weight cutting tools are often required for manual handling, tool changer requirements and smaller machine spindles. Additive manufacturing offers many innovative solutions for lightweight designs.

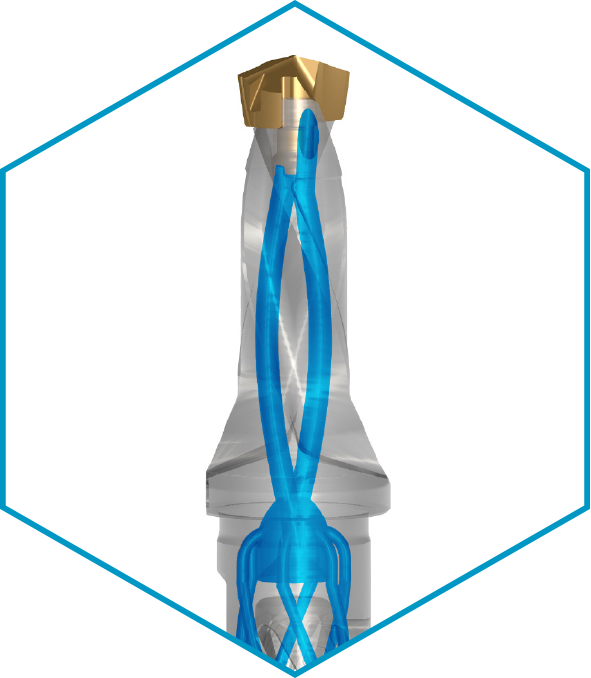

Optimized Coolant Supply

Tailor-Made Solutions

A tailor-made coolant supply can play the key role in machining.

Among other benefits, it has an impact on:

- Tool Life

- Chip Control and Chip Evacuation

- Metal Removal Rate

- Process Reliability

Ingersoll CUBE 3D will find the optimal solution for you, too!